One Stop Shop for Electrical and Mechanical Repairs

The Value of Mechanical Motor Repair

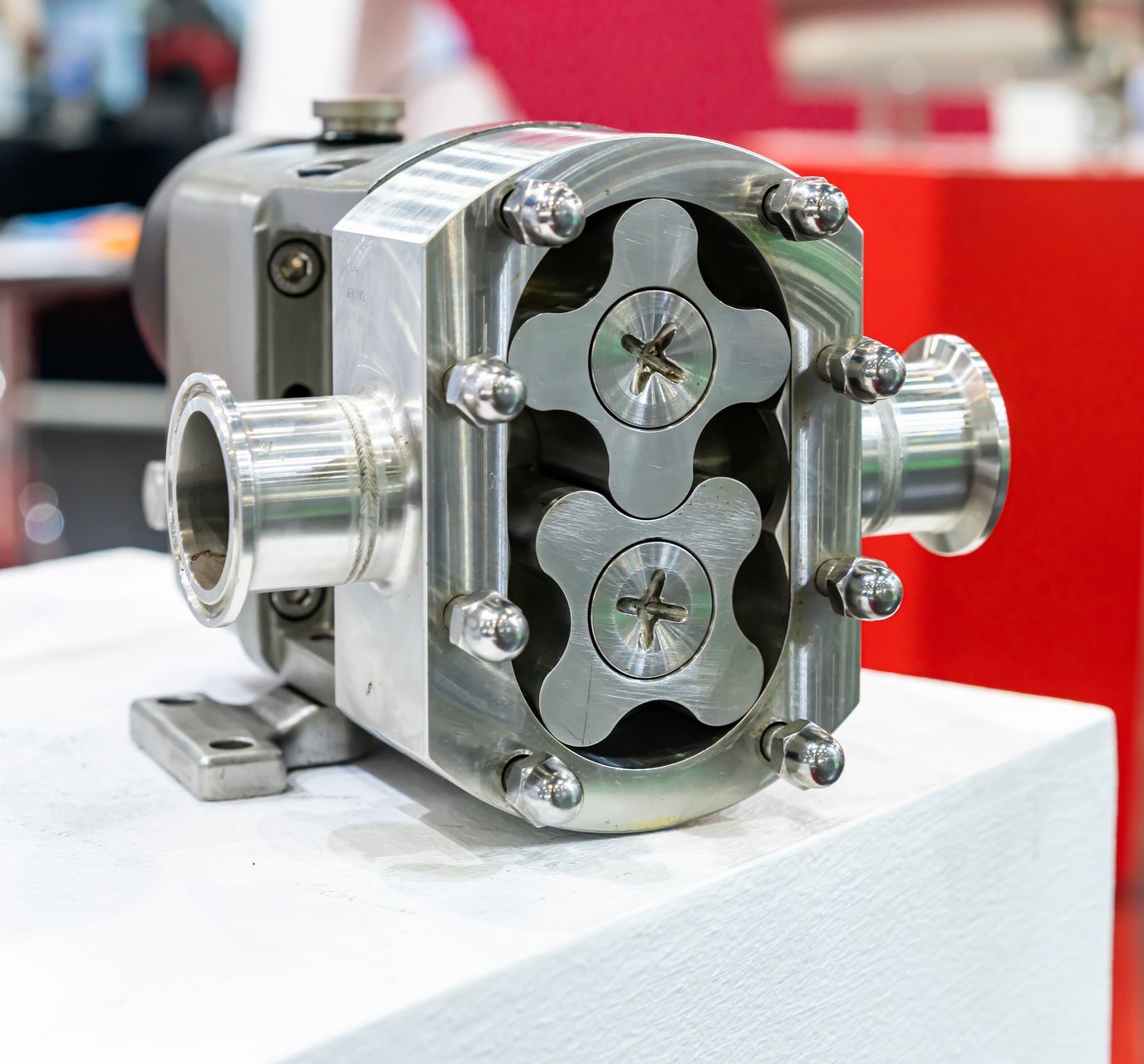

Mechanical motor repairs are carried out to get your motor into working condition again and are usually required when the AC or DC on your motor is damaged. Repairs can be more cost-effective than replacing the motor without impacting the running of your business. At times, undamaged but underperforming motors might need to be repaired or rewound.

The process of repairing the motor is based on a series of steps depending on the type of damage or underperformance that include stripping, inspecting, repairing, rewinding, balancing, reassembling, testing, cleaning, and respraying.

Once your motor has been collected and brought into the workshop, it is taken to the machine department to be stripped down. At this point, all of its components are minutely inspected by an expert technician for any faults. These faults are then repaired or rewound.

The next course of action is to take the motor to an in-house balancing machine to ensure it is balanced before being reassembled. After it has been ensured that all of the components are in good working order, the motor is tested to ensure it complies with industry standards and can withstand its usual operating conditions. Finally, the motor is cleaned and resprayed before being sent back.

What to consider when thinking of motor repairs?

An important question to consider is whether to repair or replace a damaged motor and this depends on various factors:

1. If the extent of the damage is not too significant, repairing the motor is generally a more cost-effective and environmentally friendly solution.

2. Generally, if the cost of repair is less than the cost of replacement, it is advisable to proceed with motor repair.

3. Availability of replacement parts can also influence the decision.

4. The type of motor and its application should also be considered. Some motors may have unique characteristics or specifications that make them more suitable for repair.

5. Evaluating motors not just for repair or replacement but also for energy efficiency can be beneficial.

Ultimately, the best course of action is to consult with a professional service provider experienced in motor repairs to assess the specific situation and provide expert advice tailored to your needs. They can evaluate the damage, estimate repair costs, and guide you in making an informed decision.

M R Engineering Group is your 'one stop shop' for electrical and mechanical repairs. Our repair workshop is fully equipped to refurbish, repair, and overhaul all kinds of rotating plant equipment, provided by our expert and highly skilled engineers. Furthermore, we ensure quality assurance and best practices in all our motor repairs. And of course, we offer in-house engineering excellence and unparalleled speed of service 24/7.

Contact Us

M R Engineering Group

107 ‑ 125 Bridge Street

Birkenhead

Merseyside

CH41 1BD

(Sat Nav Postcode: CH41 1AT)

© Copyright 2023 M R Engineering. All Rights Reserved.