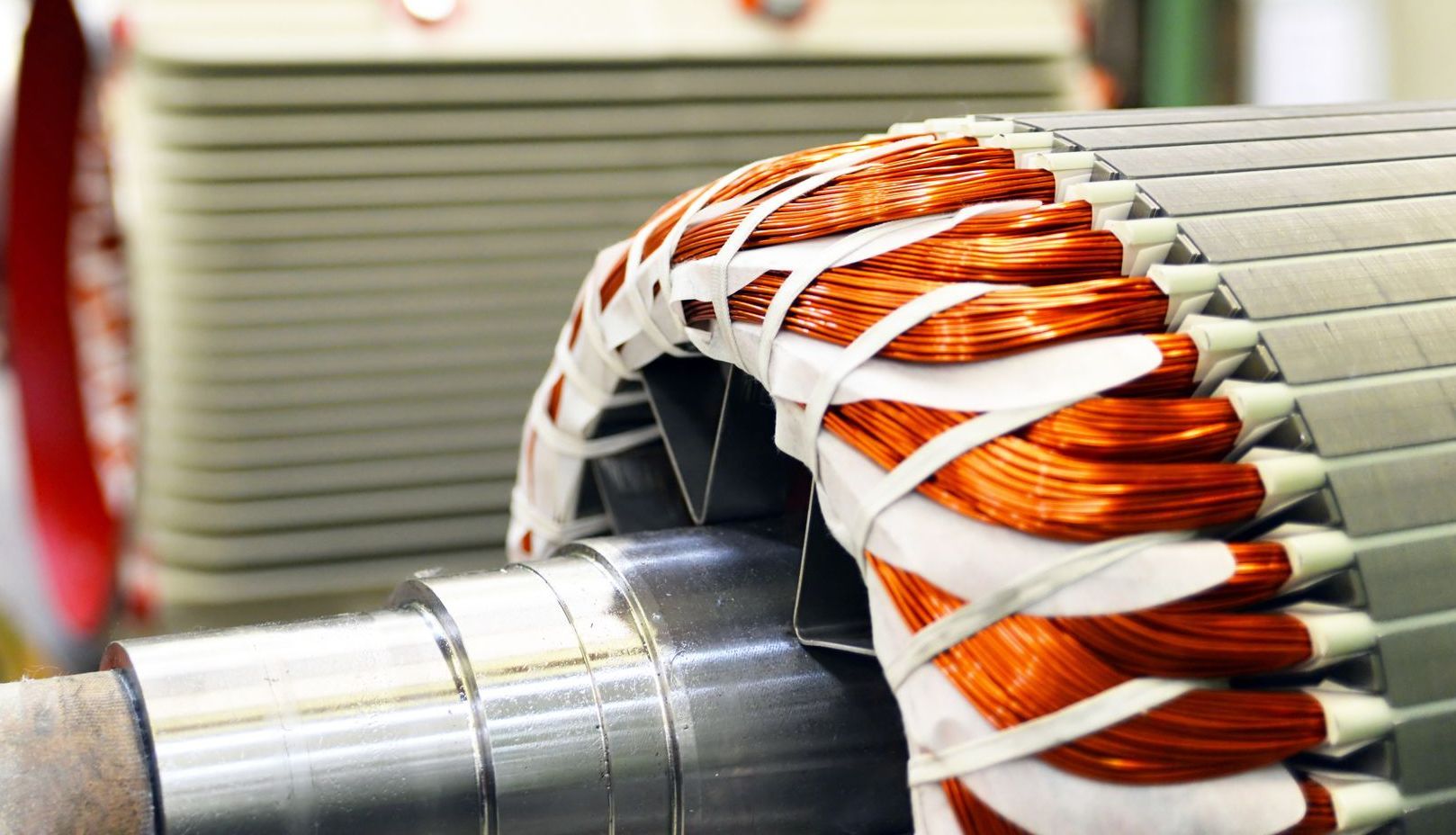

Electrical / Mechanical Repair Workshop

Our repair workshop is able to undertake the complete refurbishment, repair and overhaul of varying rotating plant equipment. Our highly skilled engineers have a wealth of experience gained over 40 years enhanced by AEMT accreditation. All of this is backed up with our quality assurance and best practice methods which ensures engineering excellence on all of our electric motor repairs.

- 24/7 Emergency Repair Service, 365 Days a Year

- Same Day/Next Day Service Available

- Experienced Team of Multi-Skilled Electro Mechanical Engineers

- Low and High Voltage Motor Rewinds and Repairs

- Repair all types of Electro-Mechanical Rotating Equipment including Electric AC/DC Motors, Generators, Pumps, Gearboxes and Fans to National Industry Standards.

- Collection of Pumps, Motors, Gearboxes, Fans etc. Complimented by Large Vehicle Hi-Ab Support

- ATEX Hazardous Motor & Pump Repairs

- Pump Repair including Centrifugal, Reciprocating, Gear and Lobe etc.

- Repair/Rewind of Submersible Pumps

- Extensive Repair Experience of New and Old Obsolete Imperial Units

- Fully Equipped Electrical Testing Bay, Core Loss Tester and DX Baker Surge Tester

- EX/ATEX Flameproof Qualified Electrical and Mechanical Repair Engineers